Strap for Spindle Control

- Excellent flexibility

- Ladder proof

- Perfect adhesion

- Oil and grease proof

- Antistatic quality

- Minimum power consumption

| Spindle driving tapes | Thickness mm. | Weight mm./mt | Coefficent of friction f | Pull for 1% elongation (N/cm) | Maximun width mm. | Welding | Applications | |

|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | Time minutes | |||||||

| NORMAL | 0.75 | 0.60 | 0.32 | 9 | 350 | 140 | 2/3 | Machines for wet spinning of hemp and flat conveyor belts up to 100 mm wide for light weights |

| COIBENT | 0.80 | 0.65 | red side 0.33 white side 0.26 |

9 | 350 | 140 | 2/3 | Wool spinning and twisting machines |

| BN/R | 0.80 | 0.82 | white side 0.26 black side 0.50 |

13 | 350 | 140 | 2/3 | Cotton and synthetic yarns spinning machines with heavy spindles and two-for-one twisters |

| HST/R | 1.20 | 1 | red side 0.29 green side 0.54 |

18 | 350 | 135 | 3 | Spinning machines with very heavy spindles and very high counterweight load |

| ZETA 1 | 0.65 | 0.60 | red side 0.60 yellow side 0.24 |

50 | 500 | 175 | 2½ | Very high speed (24.000 rpm) cotton and synthetic yarn spinning machines |

Joining system for Z1

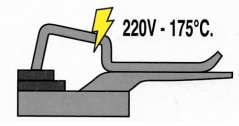

| 1) Connect the pliers to a 220V plug and wait 10 minutes before starting to weld, in order to reach the fixed temperature of 175°C. |

|

|

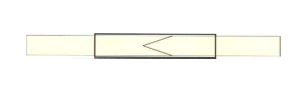

2) Cut the tape according to its working length, as in sketch. |

|

| 3) Insert the two matching ends into the teflon mask, making sure that the yellow side faces the top. |

|

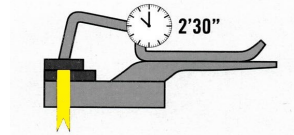

| 4) Press the mask in the heated pliers for 2’30” at 175°C |

|

| 5) Extract the mask and let cool off for 30" before removing the welded tape. |

|